2024-08-06

Supply chain is a fairly complex domain. It essentially deals in storage and movement of physical goods. While the academic generalisation of the domain exists, often, a serious e-commerce company has to build a tailored solution for itself to ensure optimal efficiency and optimal cost of operations. Before I explain this any further it will be useful to understand fundamental concepts that constitute any supply chain.

Let me start by introducing basic set of entities and concepts. It may seem overwhelming but once you understand how these entities and concepts come together it will feel very natural.

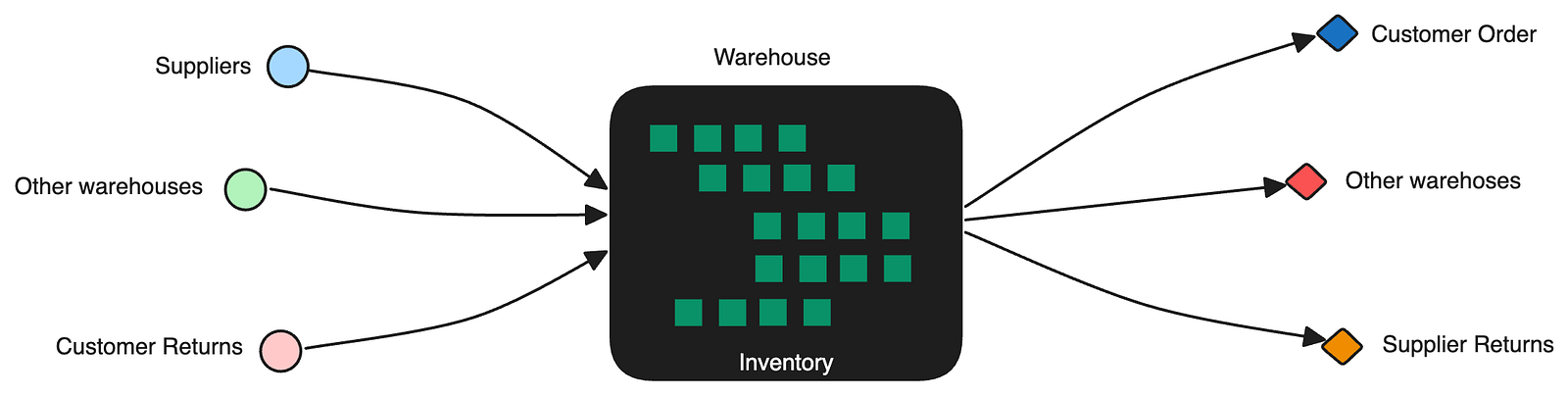

A warehouse is a long term storage of products and goods. A warehouse is an ecosystem in itself. For simplicity sake we can consider it as a big black box. This box has two gates, one for moving material into the box. This is called inwarding. The inwarded material is then stored inside this box. The second gate is for moving material out of this box. This is called outwarding or dispatch.

At any point in time we can query this box and understand what all products are there and how much quantity is lying exactly where. The material that is moving out of the second gate can have multiple destinations. It can be going to the customer, or it can be going to another warehouse, or it can be going back to the producer as it is expired or broken etc etc.

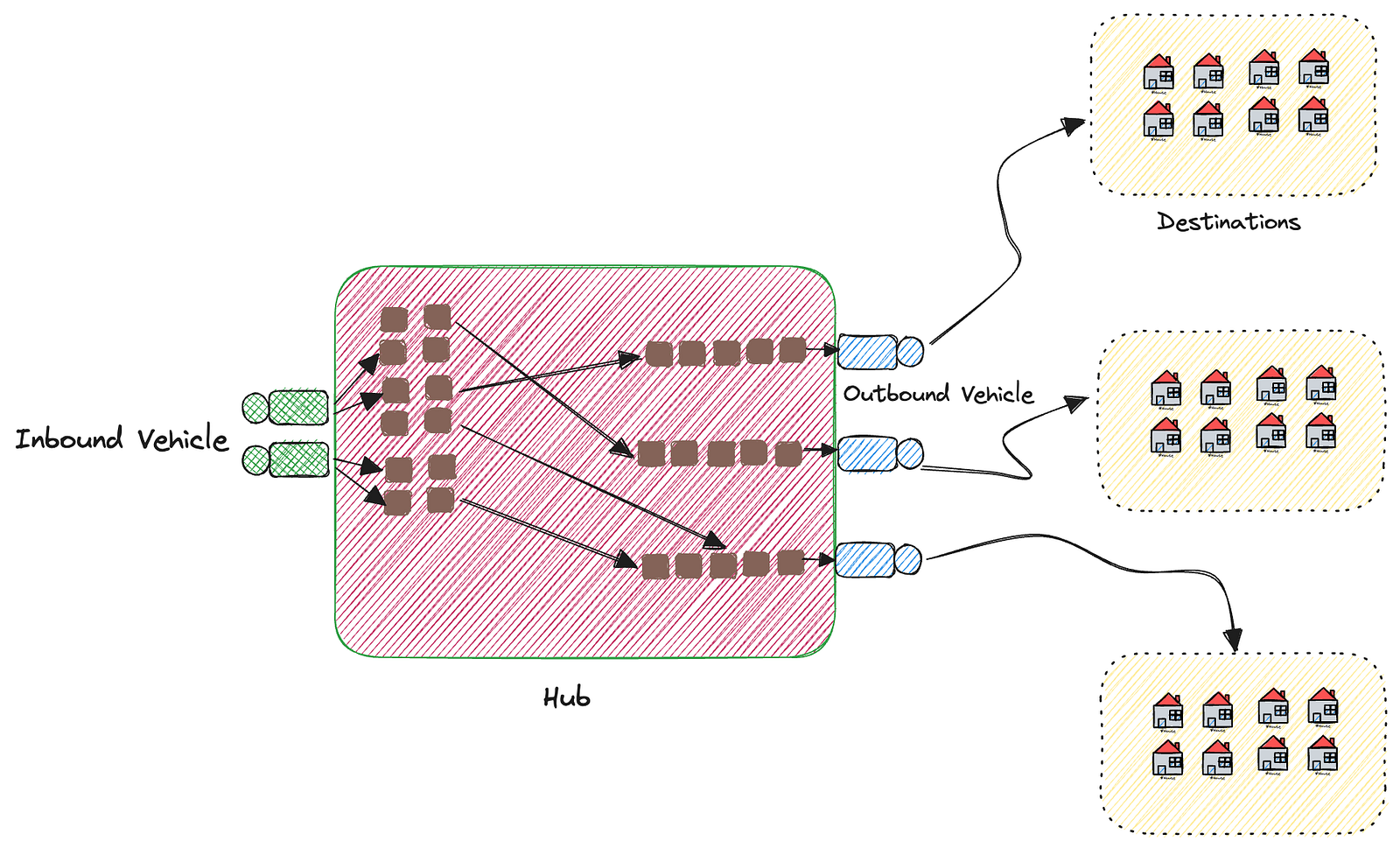

A Hub is a temporary destination for goods in transit. They are also called sortation centre. The hub receives goods from multiple sources. These goods are then sorted based on their next destination. Once sortation is done, these sorted goods are then loaded on to different vehicles towards multiple destinations. In short a Hub is like a multiplexer, with multiple sources and multiple destinations.

The main purpose of transportation is to move products physically between source and destination. All kinds of transportations like 2-wheelers, trucks, goods train, airplanes, ships etc are part of this. What means of transportation is used depends on multiple factors like --

This means that it is constrained by the physical laws. First constraint is the volume and dead weight of the product. Second constraint is the time it takes to move this product from point A to point B. Together these two constraints form the idea of capacity. Every entity in supply chain is bound by this concept. Like a warehouse has a storage capacity, its man power and other automations have a capacity of moving certain tonnage per hour within a warehouse. A lane has a capacity w.r.t the size and tonnage capacity of a truck and average speed of the truck in a given lane. Capacity has a direct implication on availability (whether the required quantity is available) and serviceability (will I be able to get the product and if yes, by when) of a product that a customer wants to order. For an e-commerce website's ability to take an order within a given delivery SLA (like next-day-delivery)it is important to know what is the current capacity of the system.

A network is a logical manifestation of how material will move from point A to point B across a large geography. You can think of it as a Directed Acyclic Graph (DAG). The nodes can represent; supplier location, warehouse, hubs, sortation centres. Edges (also called lanes) represent connection between the nodes, direction of movement of goods and the kind of goods that can be moved between these nodes. Multiple parameters come into play when deciding the network - like SLA within which goods need to be delivery, cost of transportation, overall carrying capacity of transportation through the lane.

Lets look at some simple network patterns --

Single pickup followed by Single Drop

This is the most straightforward use-case. A truck driver pickups material from the source which can be a manufacturer warehouse, wholesaler etc and drops it at a single destination. Example, a service like Dunzo doing point-to-point pick and delivery of documents.

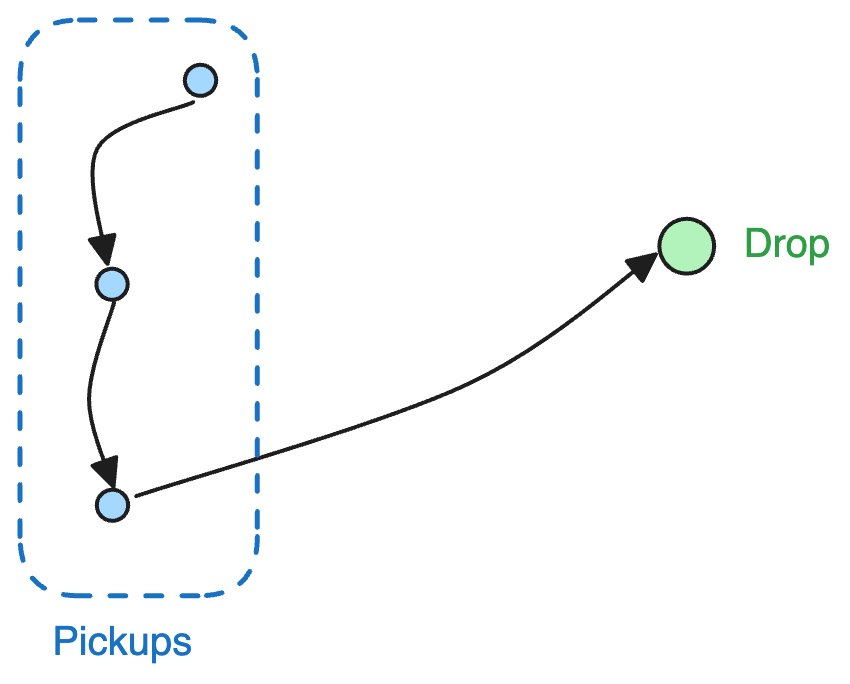

Multiple pickups followed by a single drop

This is where the driver is picking up different products from multiple suppliers and dropping it at a single customer. This is how a typical shopkeeper buy goods. They will order from multiple wholesalers and then a single vehicle will pick material from all these wholesalers and deliver it to the shopkeeper.

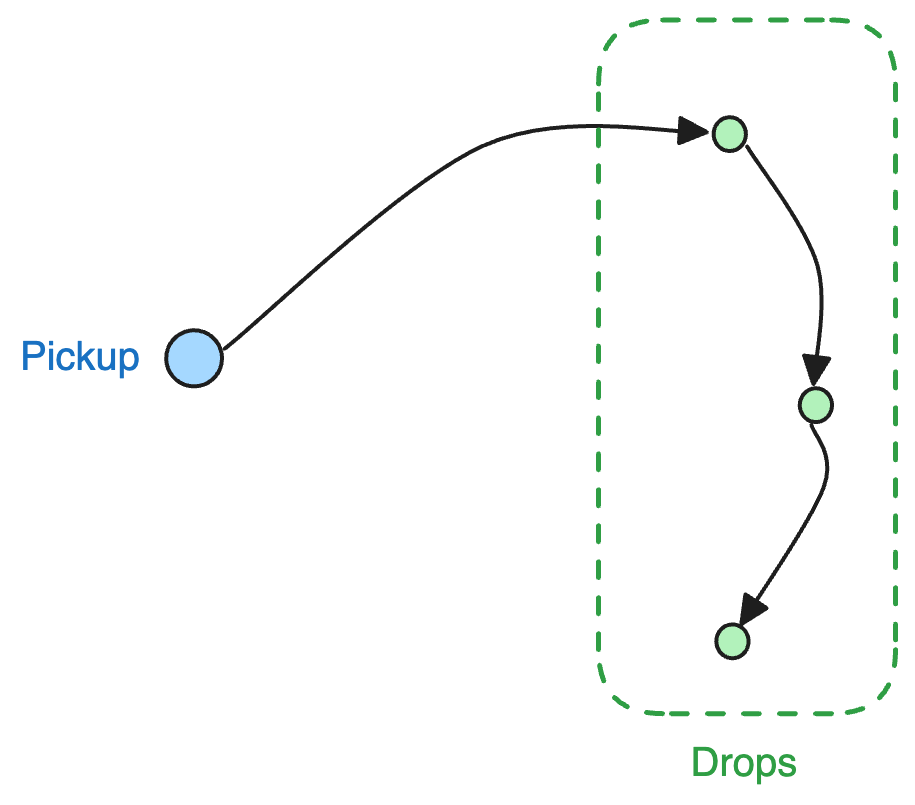

Single pickup followed my multiple drops

This is a distribution model wherein the pickup happens from a single source location and then gets distributed across multiple customers. Any last mile in a typical e-commerce supply chain or hyperlocal delivery works in this manner. The picker will pick material from a local hub or a dark-store and deliver it to one or more customers.

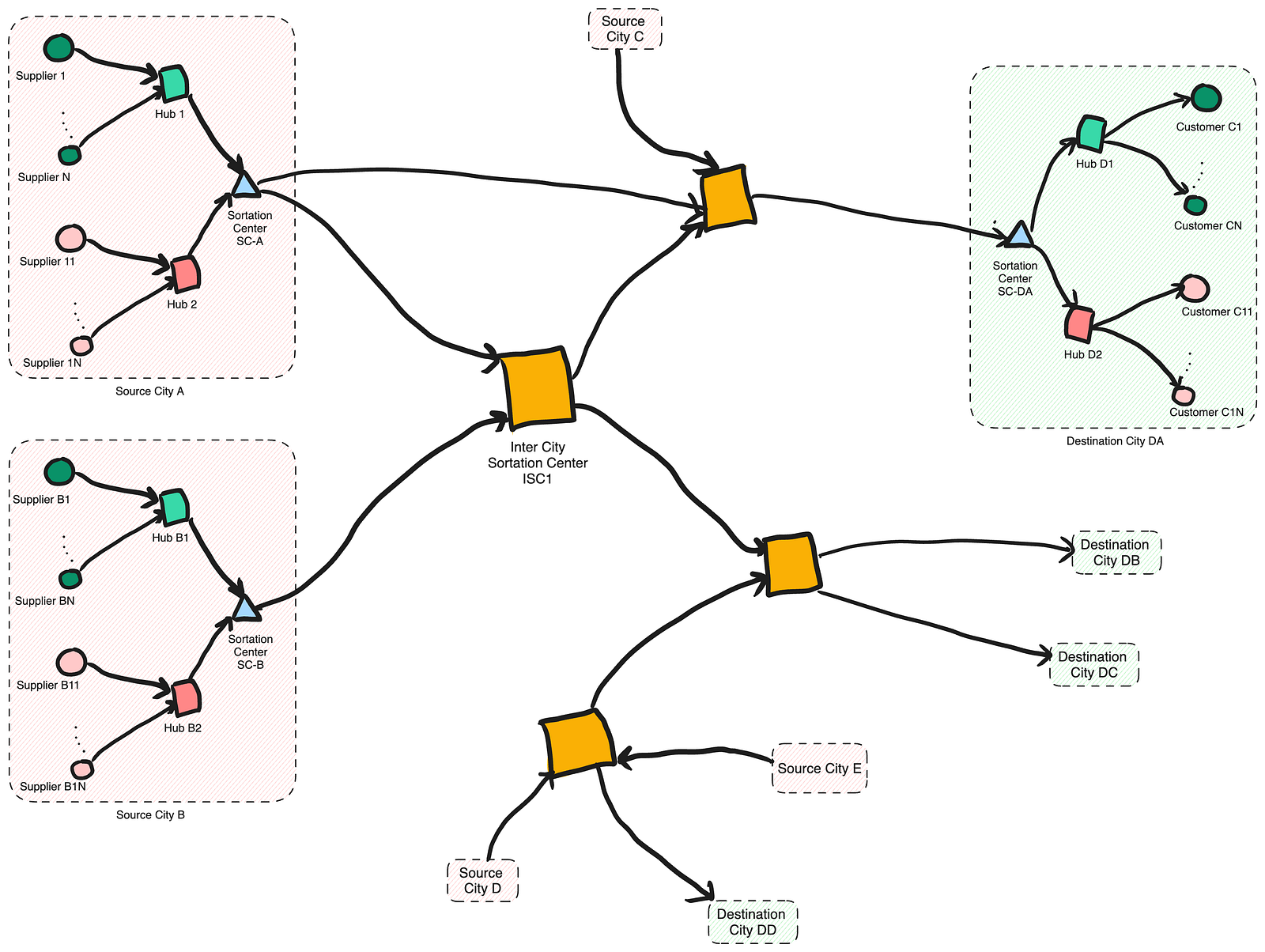

Now lets combine these entities and concepts and look how supply chain for an intercity e-commerce marketplace look like.

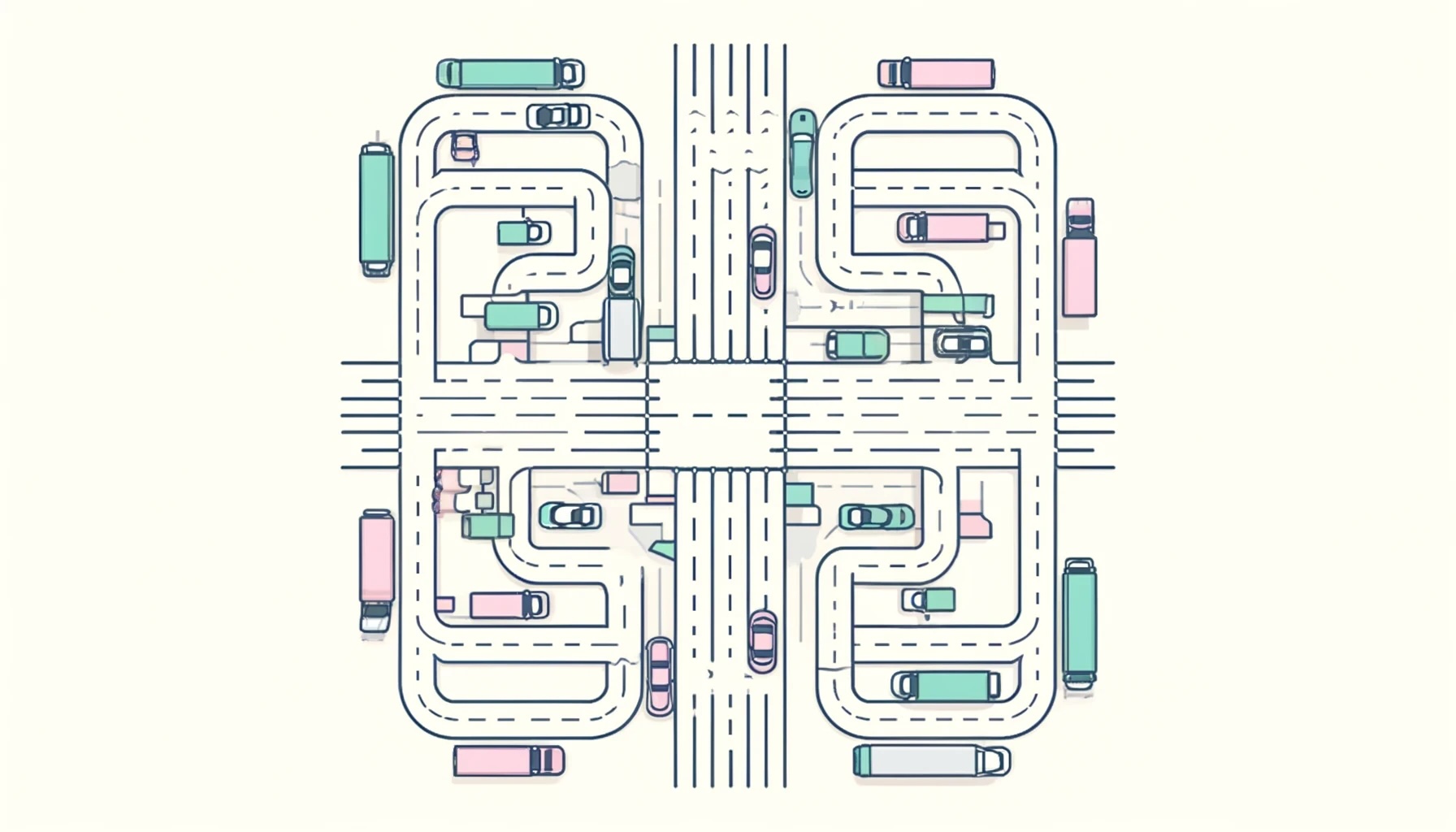

The above figures shows a typical network design of an intercity e-commerce company. Lets go through it

Network Design

The network design is one of the most critical components of any supply chain. It is a challenging problem as through the design is required to achieve multiple business goals like,

while keeping the following constraints in check -

This concludes the basics of supply chain. The Supply chain domain is really vast but the fundamentals that we covered here are not very different. The scale of operations, size of geography to be covered, local or international laws, nature of goods being transported etc adds additional layers of complexity, making this field really challenging and interesting. In future articles I will follow-up in depth details on each of these concepts. Stay Tuned!

Drawing from our experience at 2 of the largest e-commerce (b2b + b2c) in India, we at propelr.tech are uniquely equipped to help you navigate the complexities of Supply Chain management. Whether your challenges lie in logistics, Warehousing, Procurement, RVP management, or comprehensive process optimization, we can tailor solutions that fits your specific business needs with optimal technology that delivers right operational efficiency and costs.